Industrial Applications and Environmental Impacts of Barite Mining

What is Barite?

Barite (also known as Baryte or Barytes) is a naturally occurring mineral composed of barium sulfate (BaSO4). This dense, relatively soft mineral is known for its high specific gravity, chemical inertness, and low solubility. These properties make barite an essential raw material in a wide range of industries, from petroleum drilling to paint manufacturing.

Where Does Barite Come From?

Barite deposits are found across the globe, with significant reserves in countries like China, India, the United States, and Morocco. Barite ore is extracted from both open-pit and underground mines. After mining, the raw ore undergoes crushing, grinding, and purification processes to produce barite products of various grades and specifications. Generally, Barite is found in:

Hydrothermal Veins: Barite often forms in veins associated with lead, zinc, and silver ores, deposited by hot fluids circulating within the Earth's crust.

Sedimentary Deposits: Barite can form as nodules or layers within sedimentary rocks like limestone and shale.

Residual Deposits: Barite might accumulate in residual deposits formed as other minerals weather away.

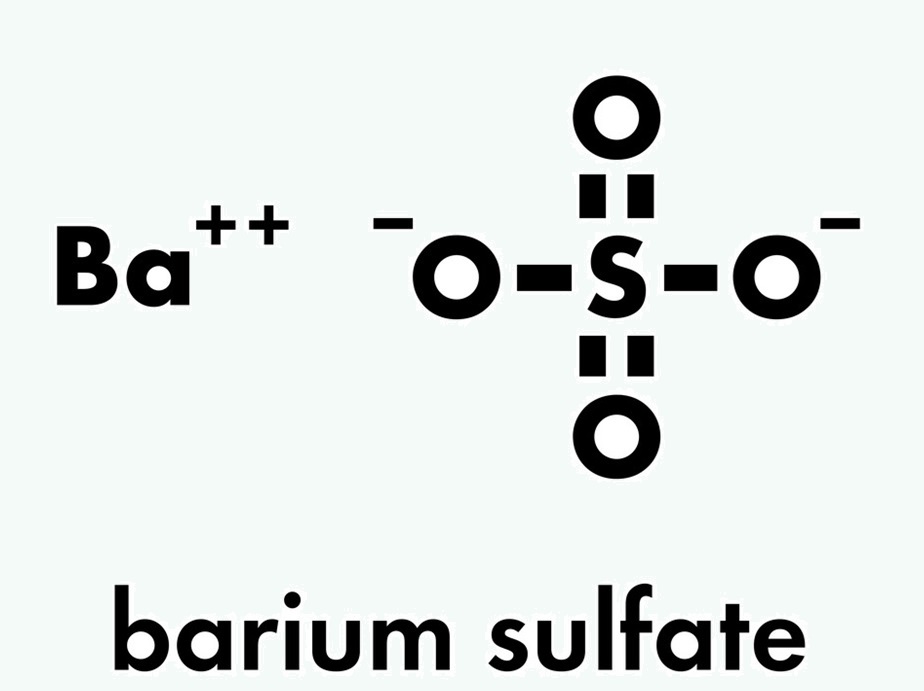

Barite Chemical Formula

Chemical Formula: Barite's chemical formula is BaSO4, composed of one barium atom (Ba) and one sulfate group (SO4).

Barite Uses

Barite has a multitude of important uses across industries thanks to Its high density, chemical inertness, and other unique properties. It is an essential component in applications ranging from oil and gas drilling to medical technology. Here’s a rundown of Barite’s more common applications:

Oil and Gas Drilling

Drilling Mud Weighting Agent: Barite's most prominent use is as a key component in drilling mud formulations. Its high density increases the hydrostatic pressure of the mud column, preventing uncontrolled blowouts of gas or oil during drilling.

Lubrication: Barite helps reduce friction and wear on drilling equipment, extending its lifespan.

Formation Sealing: Barite in drilling muds can help seal off permeable geological formations, preventing fluid loss and potential wellbore instability.

Industrial Applications

Paints and Coatings: Finely ground barite serves as a filler and extender in paints, improving flow properties, enhancing opacity, and adding weight.

Plastics and Rubber: Barite is incorporated into plastics and rubber to increase density, improve hardness, and enhance sound absorption properties.

Automotive Industry: Barite finds use in brake linings, clutch pads, and other friction products due to its thermal stability and wear resistance.

Papermaking: Barite enhances the brightness, smoothness, and opacity of certain types of paper.

Glass Manufacturing: Barite can improve the optical properties and durability of glass products.

Medical Applications

Radiocontrast Agent: Due to barium's ability to absorb x-rays, barite is used in the form of a "barium meal" or "barium enema" for diagnostic imaging of the digestive system.

Radiation Shielding: Barite's high density makes it effective as a component in shielding materials for x-ray rooms and other facilities handling radioactive sources.

Other Uses

Construction: Barite is sometimes incorporated into high-density concrete for radiation shielding purposes in certain specialized construction projects.

Soil Remediation: Barite can be used to immobilize certain contaminants in soil.

Decorative Purposes: Attractive specimens of colored or crystalline barite are used as mineral specimens or even fashioned into jewelry.

Barite Types

Barite comes in different crystal forms, including tabular (flattened), prismatic (blocky), bladed (elongated), and rosette clusters. This dense mineral also comes in a wide color spectrum. Although white or colorless barite is most common, Barite exhibits an astonishing array of colors due to the presence of impurities and trace elements within its crystal structure:

Black Barite

Black barite often gets its distinctive coloration from the presence of organic matter or finely disseminated sulfides within the mineral.

Blue Barite

Celestine (strontium sulfate), a mineral closely related to barite, can sometimes impart a beautiful blue color. Blue barite is a highly prized variety among collectors.

Golden Barite

Golden hues in barite can arise from inclusions of iron oxides or hydroxides, such as limonite.

Yellow Barite

Yellow barite may owe its color to impurities like lead or iron, or sometimes to the presence of microscopic sulfur particles.

Pink Barite

The presence of trace amounts of manganese can give barite a delicate to vibrant pink color.

Bladed Barite

Bladed barite refers more to the crystal habit or shape rather than a specific color. Barite crystals can form elongated, blade-like structures with sharp edges.

Green Barite

Greenish shades in barite can result from inclusions of copper-containing minerals or other trace elements.

Orange Barite

Orange barite can form due to the presence of iron oxides or hydroxides within its structure.

Brown Barite

Brown colors in barite typically arise from various iron impurities or oxidation within the mineral.

Fluorite Barite

This refers to barite occurring in association with fluorite, another mineral. The two minerals can grow intermixed or in close proximity. Fluorite itself exhibits a wide range of colors.

Red Barite

Reddish colors in barite can be caused by the presence of hematite (iron oxide) inclusions.

Peach Barite

Delicate peach hues in barite might be due to a combination of trace elements or inclusions, potentially including manganese and iron compounds.

Barite Twinning

Crystal twinning is a phenomenon where two or more separate crystal segments of the same mineral join together in a specific, well-defined orientation. It often occurs during crystal growth due to changes in temperature or pressure during formation, structural defects or dislocations within the crystal lattice or the presence of impurities that disrupt regular crystal growth.

This results in a seemingly composite crystal with a symmetrical arrangement of its components. Barite can exhibit several types of twinning patterns, including:

Contact Twins: Two crystals intergrow along a single plane (the twin plane), often appearing as a mirrored reflection across the twin plane.

Penetration Twins: Crystals appear to interpenetrate each other, often resulting in cross-shaped or star-shaped patterns.

Polysynthetic Twinning: Multiple, thin lamellae (layers) of twinned crystals create a fine striated pattern within the mineral.

Barite Streak

Streak refers to the color of a mineral when it's finely powdered. This is often done by dragging the mineral across an unglazed porcelain streak plate.

Why is Barite's Streak White? Even though barite can exhibit various colors, its streak is typically white. Here's why:

Impurities: The colors in barite often result from trace impurities that don't heavily influence the bulk composition of the mineral. When powdered, these impurities are diluted, and the dominant color of the unadulterated barite becomes apparent.

Hardness: Barite is softer (3-3.5 on the Mohs hardness scale) than the porcelain streak plate (around 6-7). As a softer material scratches a harder one, it leaves behind a powdered trace of its own composition.

Is Barite Safe?

Barite in its natural form (Barite Ore/Rocks) is generally considered non-toxic due to its extremely low solubility. However, prolonged exposure to barite dust can cause irritation of the lungs. Therefore safety protocols and proper handling are crucial in environments where barite dust is present. It's also essential not to confuse the relatively safe mineral barite with more dangerous soluble barium compounds.

Environmental Impacts of Barite Mining

While barite is an essential industrial mineral, its extraction and processing can have environmental consequences. Mining operations can disrupt ecosystems and habitats. Reclamation efforts are crucial to minimize long-term impacts. Moreover, barite processing requires water, potentially affecting local water resources. Additionally, mining and processing generate waste materials needing careful handling and disposal to prevent pollution.

Barite Price

The price of barite varies depending on its grade, purity, color, and market demand. Factors like barite price per ton, barite powder price, and overall barite cost are crucial for industries that utilize this mineral.

TEAMChem: Your Trusted Source for High-Quality Barite

TEAMChem, as a leading supplier of petrochemicals, understands the vital role barite plays in the oil and gas industry .We offer a range of barite products to meet the diverse needs of drilling operations:

Barite Lumps

Barite Powder (Various Grades): Including Barite 4.1 powder and Barite 4.2 powder for optimal performance.

Customized Barite Solutions: Tailored barite blends to address specific drilling challenges

Why Choose TEAM Chemicals for Your Barite Needs

TEAMChem stands out as your reliable partner for Barite supplier in Iran due to:

Quality Assurance: Our stringent quality control ensures barite products meet industry specifications, including API standards for drilling-grade barite.

Technical Expertise: Our team has deep knowledge of barite applications and can assist you in selecting the optimal products for your requirements.

Global Sourcing Network: We leverage our extensive network to locate the best quality barite at competitive prices, ensuring value for our clients.

Logistics Excellence: TEAMChem ensures timely and reliable delivery of barite to your site, minimizing operational delays.

Barite Solutions for Your Success

Whether you require barite for paint, barite for drilling mud, or any other industrial application, TEAMChem has the resources to fulfill your needs.

Let's Talk Barite. Contact Us Today!

Don't let barite sourcing be a challenge. Contact TEAMChem to discuss your requirements and discover how our barite solutions can enhance your operations. Experience firsthand our exceptional customer service, reliable supply chain, and commitment to delivering the highest quality barite products.