Barite(also known as baryte) is a mineral primarily composed of barium sulfate (BaSO4). It's commonly white or colorless, but impurities can cause yellow, gray, blue, or brown hues. It can crystallize in various forms like tabular crystals, rosettes, or fibrous masses. Barite is known for its exceptional density, chemical inertness, and ability to block X-ray and gamma-ray emissions.

Barite is mostly used as a weighting agent in drilling muds in the oil and gas industry. However, its unique properties extend its reach far beyond, impacting a surprising array of industries. This article takes a deep dive into barite, exploring its characteristics, uses, production methods, environmental considerations, and its importance in global industrial processes.

What Exactly is Barite?

From captivating barite crystals and barite rose formations to essential barite powder (or barytes powder if you may), this mineral goes a long way to support energy security, create jobs in mining, processing and transportation, and to drive economic growth.

Under the Hood: Composition & Properties

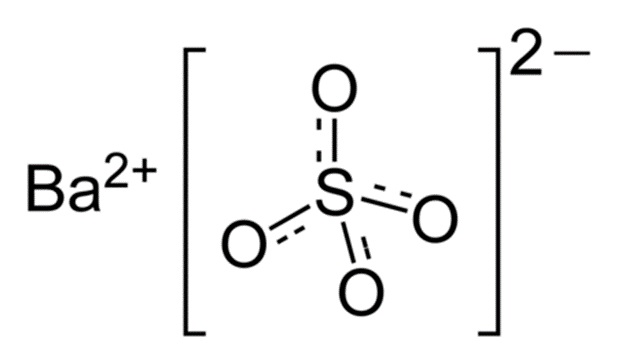

Barite - as the formula (BaSO4) suggests - consists of barium (Ba), sulfur (S), and oxygen (O). With a specific gravity of around 4.5, it is exceptionally heavy for a non-metallic mineral. The name barite comes from the Greek word "barys" meaning "heavy," referring to its defining characteristic. Besides High Density, other notable properties of barite include:

Chemical Inertness:

Resistant to most acids and alkalis.

Doesn't easily dissolve or react with other substances.

Opacity to X-rays and Gamma-rays:

Its high density and atomic structure allow it to block these high-energy radiations effectively.

Low Hardness:

2.5 to 3.5 on the Mohs hardness scale, meaning it can be scratched relatively easily.

Cleavage:

Exhibits three directions of perfect cleavage, meaning it breaks cleanly along specific planes.

Very Low Water Solubility:

Barite is extremely insoluble in water. Its solubility product (Ksp) is approximately 1.08 x 10^-10, indicating that only a minuscule amount of barite will dissolve under standard conditions.

Desert Rose: Barite's Lesser Known Side

While I have your attention, let's talk about some of barite’s lesser known talents. Did you know some barite specimens glow under ultraviolet (UV) light, fluorescing in shades of yellow, blue, or white?

Even more captivating, did you know barite can form stunning natural sculptures known as "desert roses”? These intricate formations occur when barite crystallizes around sand grains in arid environments.

In certain environments, barite can replace and preserve the intricate structures of fossils. It is also used in some specialized geologic dating techniques given it can slightly incorporate radioactive elements.

Traditional Uses of Barite in Oil and Gas Industry

The oil and gas industry heavily relies on barite as a weighting agent in drilling muds. These essential fluids pumped down the wellbore manage pressures, lubricate the drill bit, and transport cuttings back to the surface. Barite's density allows it to significantly increase the mud's weight, preventing blowouts and ensuring safe drilling operations. Its chemical inertness ensures stability of drilling fluid systems while its inert softness helps reduce friction and prevent damage to drilling equipment.

While increasing density is its primary function, in some specialized cases, barite containing trace amounts of radioactive elements is added to drilling mud. Measuring natural gamma radiation from this barite can help geologists identify specific rock formations and make drilling decisions.

Beyond Oil and Gas: Exploring Lesser-Known Applications

While approximately 70-80% of global barite consumption caters to drilling operations, barite's unique properties lead to its application in a surprising array of other industries. Let's explore some of the diverse and unexpected ways barite contributes to modern technology and manufacturing:

Barite in the Medical Field: Radiological Imaging and Therapy

Remarkably, barite, this crucial component of drilling muds, has medical applications as well. Its unique ability to both enhance and block radiation makes it a valuable tool for both diagnostic imaging and safety protocols.

Radiocontrast Agent: Patients often ingest a barium sulfate suspension before X-rays or CT scans. Barite's high density and ability to block X-rays create clear contrast within the digestive system. This allows for enhanced imaging and more accurate diagnoses.

Radiation Shielding: Concrete or plaster containing barite is used to construct walls and barriers that protect patients and healthcare workers from harmful radiation during imaging procedures and radiation therapy.

Barite in Construction: Heavy Concrete and Radiation Shielding

Barite has found increasing importance in construction, thanks primarily to its exceptional density. It is a valuable tool for creating specialized concrete and enhancing soundproofing properties within buildings.

Heavy Concrete: Barite serves as a dense aggregate in specialized concrete mixes. This high-density concrete finds use in counterweights, ballast blocks, and, importantly, radiation shielding. Nuclear facilities, power plants, and medical complexes rely on barite concrete for its vital protective qualities.

Soundproofing: Adding barite to construction materials improves sound dampening properties. This denser material reduces noise transmission within buildings, creating quieter and more comfortable living and working environments.

Barite in Paints, Coatings, and Plastics Industries

From drilling wells to coating surfaces, barite's high density plays surprisingly diverse roles, including applications within the paint and plastics industries:

Filler and Extender: Barite acts as a valuable filler in paints, coatings, and plastics. Its inert nature makes it particularly suited for anti-corrosive coatings, and its density contributes to abrasion resistance. Barite improves the flow properties, durability, and overall performance of these coatings, protecting surfaces in various environments.

Density and Weight: Barite powder adds density and weight to plastic and rubber products for specific applications. White barite is commonly used, while some applications might utilize colored variants like blue barite, golden barite, or even yellow barite.

Examples include marine paints for superior protection against harsh saltwater environments, barite lumps used for weighting applications, and specific components in rubber flooring or industrial belts where weight influences their functionality.

Barite in Automotive Applications: Friction Materials and Soundproofing

When it comes to automotive performance, barite works behind the scenes to deliver important benefits. From the efficient stopping power of your brakes to the reduced vibrations within your car, barite enhances both safety and ride comfort.

Brake Pads and Clutch Linings: Barite finds its way into a surprising place within your vehicle – the brakes! It enhances the friction properties of brake pads and linings, offering consistent performance and reduced wear. Additionally, barite helps dissipate the heat generated during braking, extending the lifespan of these essential components.

Noise Reduction: Certain automotive components utilize barite-filled materials to minimize vibrations and noise levels. This contributes to a smoother, quieter ride. A common example is noise-reducing compounds used in the car's undercarriage or within body panels to create a quieter cabin experience.

Barite in Paper and Textile Industries: Weighting Agents and Additives

Barite's journey extends into the realm of everyday products. Finely ground barite takes on a new role in paper and textiles. From brighter, smoother paper to fabrics with improved drape and weight, barite adds both practical and aesthetic value.

Paper Coatings: Finely ground, white barite (also sometimes called barite white) plays a role in papermaking. It improves the brightness, smoothness, and printability of paper and paperboard. Its high density also gives paper products a more substantial and luxurious feel.

Textile Fillers: In the textile industry, barite adds both weight and density, affecting the drape and flow of fabrics. This can alter the hand feel for specific design requirements. For instance, some fabrics might incorporate pink barite to achieve a specific aesthetic or barite noodles for a unique textural effect.

Environmental Considerations and Barite Mining

Barite itself is largely non-toxic and chemically stable, making it a relatively safe material to handle. However, responsible barite mining and processing are crucial to minimize environmental impacts. Key factors to consider include:

Potential Contaminants: Barite deposits can sometimes contain trace elements of toxic heavy metals. Careful handling, extraction methods, and processing minimize the release of these impurities into the environment to protect ecosystems.

Drilling Mud Disposal: When used in drilling fluids, responsible disposal practices must prevent contamination of land and water resources.

Reclamation: Sustainable barite ore mining incorporates comprehensive plans for site reclamation, restoring and protecting previously mined lands, minimizing the industry's footprint.

Resource Efficiency: Companies like Team Chemicals, specializing in barite and other industrial minerals, continually optimize their processes and supply chains to ensure the most efficient and sustainable use of this valuable resource. Responsible sourcing and refinement practices reduce waste and minimize the need for additional extraction.

Future Prospects: Emerging Applications and Innovations in Barite Utilization

The future holds exciting possibilities for barite. As researchers delve deeper into its potential, innovative applications are emerging that could revolutionize energy storage and environmental remediation. This section explores two promising areas: barite's role in thermal energy storage systems for a more sustainable energy future, and its potential as a game-changer in removing harmful contaminants from water.

Energy Storage

Barite’s high heat capacity makes it a promising candidate for thermal energy storage systems. Barite absorbs a lot of heat energy with a minimal rise in its own temperature. Barite composites, materials combining barite with other components, could be incorporated into various thermal energy storage systems, including:

Concentrated Solar Power Plants: These plants collect sunlight and convert it into heat. Storing this thermal energy using barite composites would allow for electricity generation even during periods without sunlight.

Waste Heat Capture Systems: Industrial processes often generate significant waste heat. Barite composites could capture this heat and release it later for various applications, improving overall energy efficiency.

District Heating Applications: In district heating systems, heat is produced in a central location and then distributed to buildings. Barite composites could store excess heat during off-peak hours and release it during peak demand periods, optimizing energy use within a district.

While barite offers advantages like abundance, affordability, and good chemical stability for thermal storage, there are also challenges to consider. Its weight and the development of efficient heat transfer methods for barite composites are key areas that require further research and development.

Environmental Remediation

Experiments investigate barite's ability to remove heavy metals and other contaminants from water. This potential application could offer innovative solutions for water treatment and pollution control, utilizing the naturally occurring properties of the barite mineral for environmental benefit. Here's what barite offers:

Heavy metal removal likely occurs through ion exchange or adsorption processes. In ion exchange, barite ions trade places with heavy metal ions in the water, effectively capturing them within the barite structure. Adsorption involves the attraction and clinging of heavy metal ions to the surface of barite particles.

Barite might be particularly effective in removing specific heavy metals like lead, mercury, and arsenic, which are common contaminants posing significant health risks.

Utilizing barite for water treatment has its own set of benefits and limitations. On the positive side, barite is naturally abundant and relatively inexpensive. However, its effectiveness can be influenced by the specific water chemistry (e.g., pH, presence of other ions). Additionally, after capturing contaminants, barite may require regeneration to be reusable, and efficient regeneration methods need to be developed.

By addressing these opportunities and challenges, researchers can unlock the full potential of barite in these emerging applications, contributing to a more sustainable future for energy storage and environmental remediation.

Bonus: Need to Know More

Where is Barite Found?

Geological Settings:

Hydrothermal Veins: Barite often forms in veins associated with lead, zinc, and silver ores.

Sedimentary Deposits: Found in limestone, sandstone, and shales.

Residual Deposits: Result from the weathering of barite-containing rocks.

Hot Spring Deposits: Rarely found near hot springs as a byproduct.

Major Barite Producers:

China

India

United States

Morocco

Mexico

Iran

Turkey

How is Barite Mined and Processed?

Mining:

Open-pit Mining: Common where barite is close to the surface.

Underground Mining: For deeper deposits.

Processing

Crushing and Grinding: Reduce barite to specified sizes.

Beneficiation: Methods like flotation or jigging separate barite from impurities.

Meeting Specifications: Processed barite must meet standards set by the American Petroleum Institute (API) for use in drilling.

Team Chemicals: Your Partner in Sustainable Barite Solutions

From the X-ray room to the vehicles we drive and the homes we live in, barite plays a silent but significant role in enhancing our daily lives. As research continues to uncover novel applications, the future of this fascinating mineral seems even brighter, potentially impacting industries and areas of our lives we haven't yet considered. Companies dedicated to responsible mineral sourcing and utilization, like Team Chemical, will play a role in shaping this future.